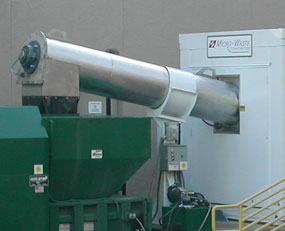

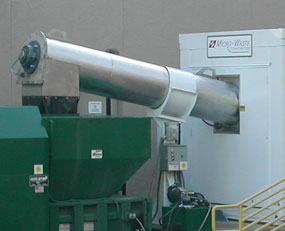

MICRO-WASTE® DISINFECTION SYSTEM®

MODEL MDS-2481

Micro-Waste Corporation® manufactures, sells and installs its newest regulated medical waste disinfection system, the Model MDS-2481, which uses moist heat for the disinfection process. This process, using microwaves assisted by steam being applied to pre-shredded waste, meet the regulatory requirements for the jurisdiction in which it is installed.

The system disinfection efficacy has also been successfully tested by two independent laboratories using a standard disinfection test protocol of Bacillus atrophaeus [or Bacillus subtilis (Niger)] spores at a 6 log10 disinfection level, 100 times greater than the 4 log10 as generally recommended by the State and Territorial Association on Alternative Treatment Technologies (STAATT). The system has also been successfully tested by an independent laboratory with the following microorganisms:

Type |

Microorganism |

Log10 Reduction |

Bacterial Spores |

Bacillus atrophaeus (ATCC 19659) |

6.0 |

Bacterial Spores |

Geobacillus stearothermophilus (ATCC 7953) |

6.0 |

Vegetative Bacteria |

Staphylococcus aureus (ATCC 6538) |

8.09 |

Mycobacteria |

Mycobacterium phlei (ATCC BAA-486) |

7.90 |

Fungi |

Candida albicans (ATCC 18804) |

8.38 |

Viruses |

MS-2 Bacteriophage (ATCC 15597-B1) |

6.01 |

Parasites |

Giardia lambia spp. cysts |

6.15 |

The following is a description of the equipment manufactured by Micro-Waste®:

1. The operator loads the waste into the system using the operator control panel. The waste cart with waste is lifted and dumped into the hopper.

2. The waste fall into the hopper and onto the counter-rotating shredder cutters to be shredded. The MDS-2481 has thicker cutters and a larger classification screen for increased throughput and higher durability.

3. The shredder provides a high torque shear shredding with its counter-rotating cutters and spacers. The shredder is uniquely designed for Micro-Waste® based upon its more than 20 years of experience operating and maintaining regulated medical waste shredders. The shredder design allows for raising the shredder classification screen external to the shredder to maintain high shredder throughput, and allows for the shredder to be quickly disassembled from the system and rolled out of the unit for external repair or immediate replacement. The transfer area below the shredder has improved photosensor detection and better access for maintenance.

4. The shredded waste is moistened with superheated steam. The steam generator has 50% more capacity than previous systems and has a filter system and an automated flush system to minimize sediment buildup.

5. The shredded, moistened waste is heated with microwaves using eight (8) 2.0 kW (nominal) microwave generator (MWG) power supplies. The 8 MWGs are an increase from the 4 or 6 MWG on previous moist heat disinfection systems sold by Micro-Waste. The microwave generators are exclusive to Micro-Waste Corporation®, include on-board programmable logic controllers (PLCs) for system monitoring and troubleshooting, and are manufactured in the USA. The microwave energy injection on the MDS-2481 is also improved to provide more even energy distribution throughout the waste.

6. The Model MDS-2481 does not have a temperature holding section as on previous moist heat disinfection models, simplifying and doing away with the additional discharge screw, gearbox, motor and waste level controls. The disinfected waste is discharged into a solid waste compactor for disposal at a landfill in accordance with applicable regulations.

7. The system is controlled by a state-of-the-art programmable logic controller (PLC). The operator main control panel has a digital touch screen for operator ease and simplified fault management.

8. The local operator control provides a simple two button operation with indicator lights providing the relevant system status.

9. The PLC and digital control panel can be monitored in real-time off-site by operations management. They can also be monitored and modified in real-time off-site by hospital management or Micro-Waste® (with owner permission) to facilitate troubleshooting, software upgrades, and regulatory reporting.

10. The shredder is easily removed on the proprietary shredder trolley system designed and manufactured by Micro-Waste®.

11. The complete shredder, gear box, speed reducer and motor can be exchanged in 4 to 6 hours.

Click for Micro-Waste® Disinfection System® Model MW-250S

Click for the ABB Sanitec, Inc. Microwave Disinfection Units Sold by Micro-Waste® |